Perma-Sort®

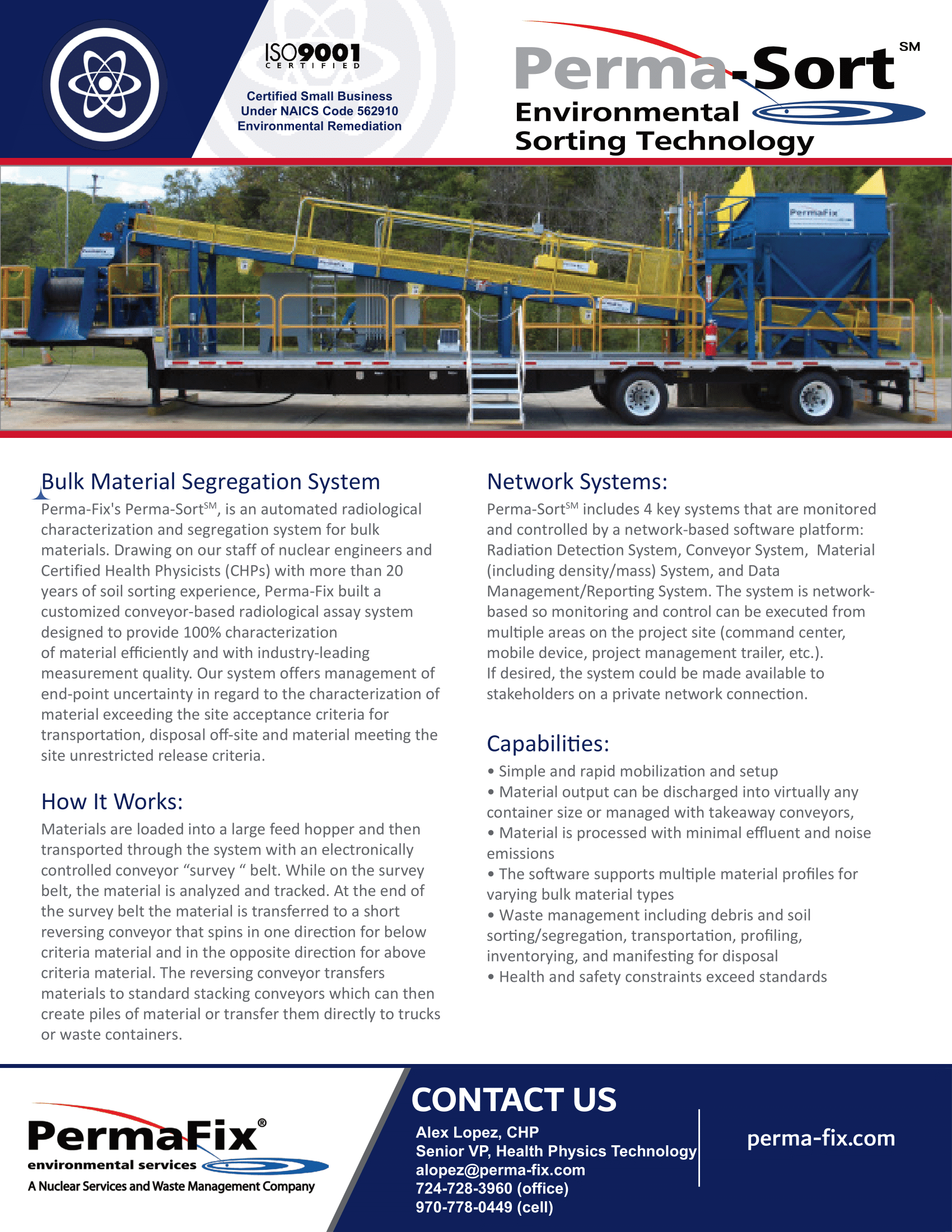

Perma-Sort® is an automated radiological characterization and segregation system for bulk materials with a customized conveyor-based radiological assay system, designed to provide 100% characterization of material efficiently and with industry-leading measurement quality. Our system offers management of end-point uncertainty regarding the characterization of all material processed, including material exceeding the site acceptance criteria (requiring transportation and disposal offsite) and material meeting the site acceptance criteria (i.e. unrestricted release criteria).

Product Specs

-

Faster Mobilization

Trailer mounted system offering simple and rapid mobilization and setup.

-

Bulk Material Characterization and Segregation

100% assay of material using conveyor-based system. Material output can be discharged into virtually any container size or managed with takeaway conveyors.

-

Processing Rates

Capable of processing > 200 tons of bulk material per hour. Software supports multiple material profiles for varying bulk material types.

-

Customizable

- Detector type(s), number, and configuration are customizable, depending on the site-specific requirements and contaminants of concern.

Applications

-

Characterization/Segregation of most flowable material types:

- Soil

- Shredded wood, metal, debris, DAW

- Crushed concrete and building material

-

Assay Objectives can support:

- Characterization

- FSS for free release

- Release with industrial controls

- Waste acceptance criteria for disposal

-

Supports a Broad Range of Contaminants:

- Fission products

- NORM/TENORM

- Transuranics

- Heavy metals

- Beryllium

- UXO/MEC

-

MEETS/EXCEEDS OSHA AND ANSI CONVEYOR STANDARDS:

- E-stop technology of conveyors

- Fall protection

- Audio and visual alarms for system operation and conveyor startup

Perma-Sort Product Lead

How It Works

Materials are loaded into a large feed hopper and transported through the system via an electronically controlled conveyor survey belt. While on the survey belt, the material is analyzed and tracked. At the end of the survey belt, the material is transferred to a short reversing conveyor. This conveyor spins in one direction for below-criteria material and the opposite direction for above-criteria material. The reversing conveyor then transfers materials to standard stacking conveyors, which can create piles of material or transfer directly to trucks or waste containers.

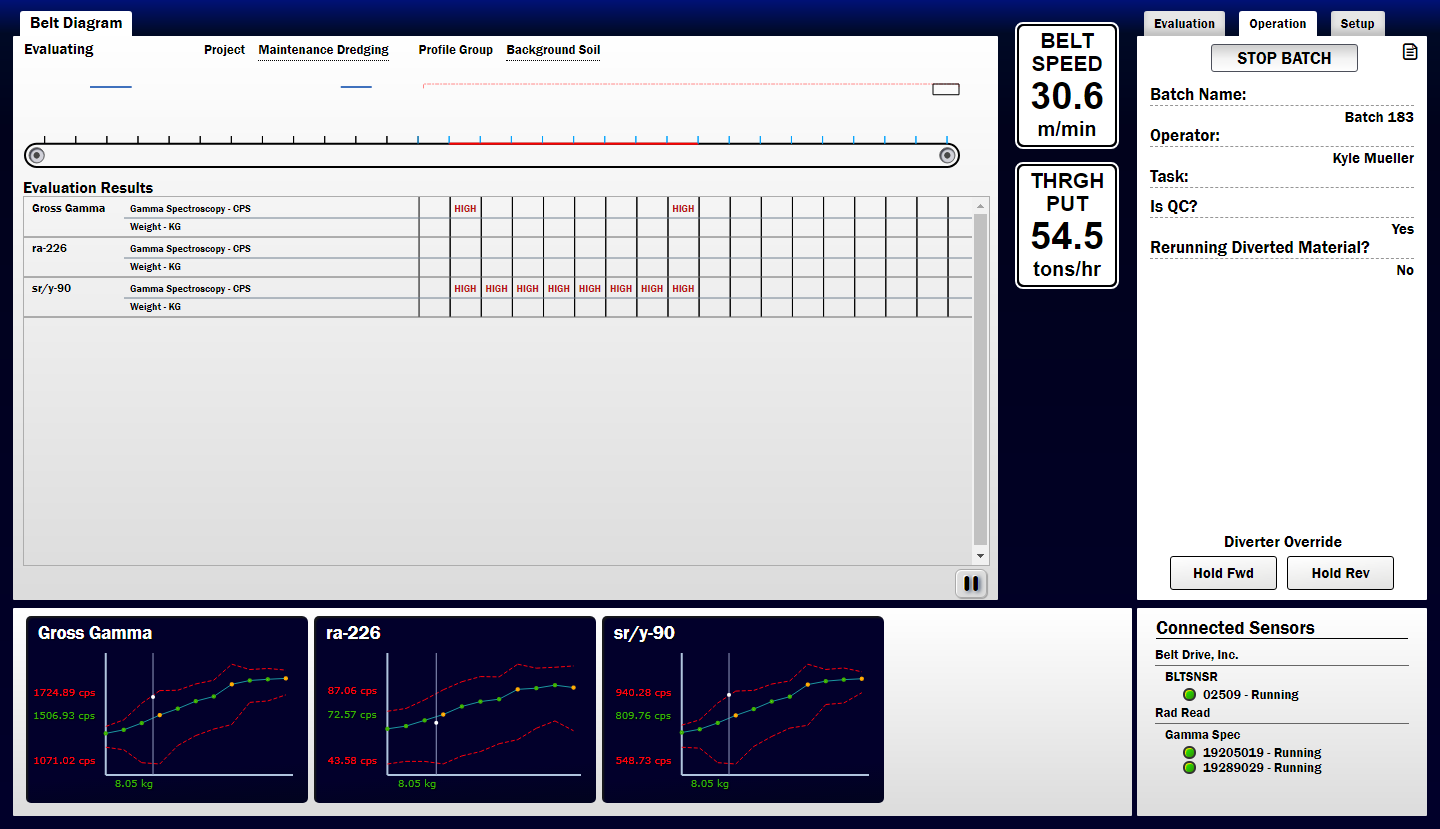

Network Systems

Perma-Sort® integrates four key systems monitored and controlled through a network-based software platform: radiation detection, conveyor, material (including density and mass), and data management/reporting. This networked setup allows monitoring and control from various locations onsite (such as command centers, mobile devices, or project management trailers). Additionally, the system can be accessed by stakeholders via a private network connection, if desired.